There are three mounting options.

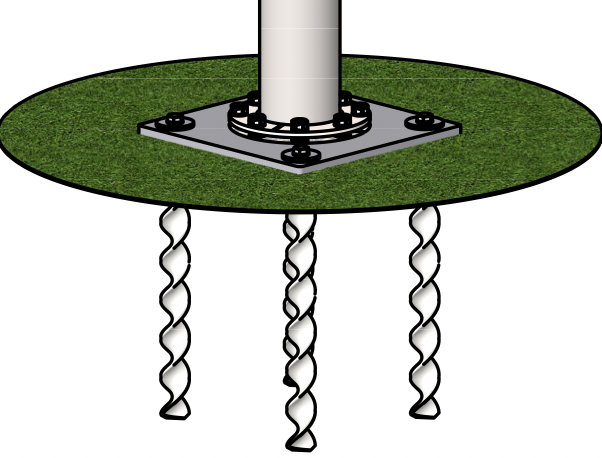

Ground anchors:

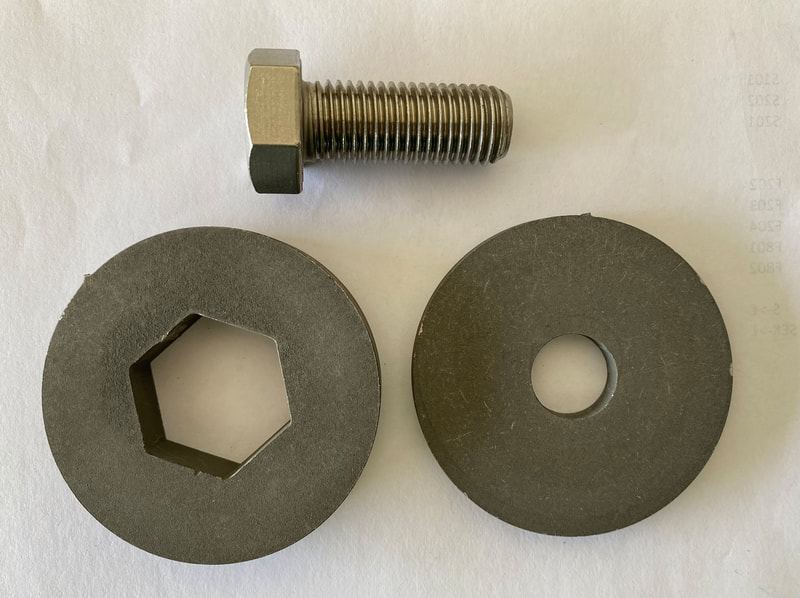

We have custom base plates and 1.2 metre ground screws (anchors) in stock for mounting your Heliomotion system in your garden or commercial location. (NB Soil requirements: undisturbed ground, clay or heavy soil - not recent building site. Soil with a high sand content is not suitable without the extra screw barbed covers, or a concrete collar.) Four ground screws can be installed in less than an hour. Atlas Copco Cobra PROe Floor Breaker HEX 2-Stroke 25 KG* is the tool required & it is available to rent by the day from Speedy Tool Hire and HSS. (Speedy Hire refer to it as Atlas Copco Cobra, Code 11/0535-h. HSS refer to it as Heavy Duty Petrol Breaker, code 02116. NB - YOU SHOULD ORDER THIS IN ADVANCE FROM SPEEDY HIRE OR HSS TO MAKE SURE IT IS AVAILABLE ON THE REQUIRED DAY.) You may also find standing on a step or 18" platform makes it easier to install the anchors at the correct vertical angle. Baseplate fixes to flanges at the bottom end of the foundation column. Quick and easy to install, and can be removed when required. No digging or waiting for concrete to cure, and the best option if the systems might need moving in the future. (*NB Adaptor stem that fits over the top of each anchor is required for use with Cobra. We can supply this from stock as a loan against a refundable deposit of £200.00 + VAT, or as a purchase for the same amount. A hammer cap, price £45.00, can be supplied if starting the install manually using a sledge hammer. (IMPORTANT: DO NOT HIT THE TOP OF AN UNPROTECTED ANCHOR AS YOU MAY DAMAGE THE THREAD) As you can see in these images, the base plates are attached with heavy duty washers and bolts, and the flanges hold the column in place. We recommend using a thread locking fluid, such as Loctite 603, on the base plate fastenings for added safety if you are in a windy area.

If the anchors need moving: they have a 28MM hex which can be counterrotated with a spanner, ratchet, sliding T-bar etc. This link is a cost effective and easy solution.

https://www.zoro.co.uk/shop/not-categorised/not-categorised/sliding-t-bar-3-4inch-sq-drive/p/ZT1229109P

Completed with ¾ inch drive 28MM socket and steel tube to extend bar length and increase leverage.

If the anchors need moving: they have a 28MM hex which can be counterrotated with a spanner, ratchet, sliding T-bar etc. This link is a cost effective and easy solution.

https://www.zoro.co.uk/shop/not-categorised/not-categorised/sliding-t-bar-3-4inch-sq-drive/p/ZT1229109P

Completed with ¾ inch drive 28MM socket and steel tube to extend bar length and increase leverage.

Concrete:

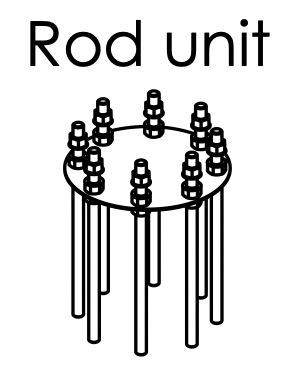

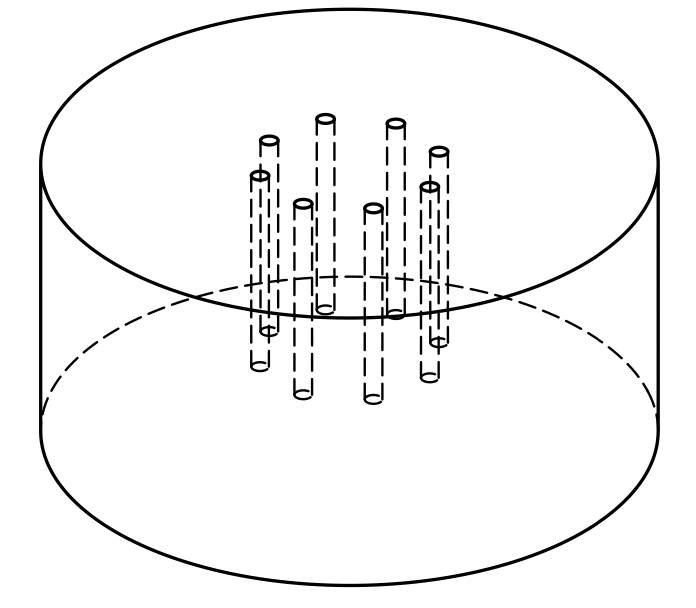

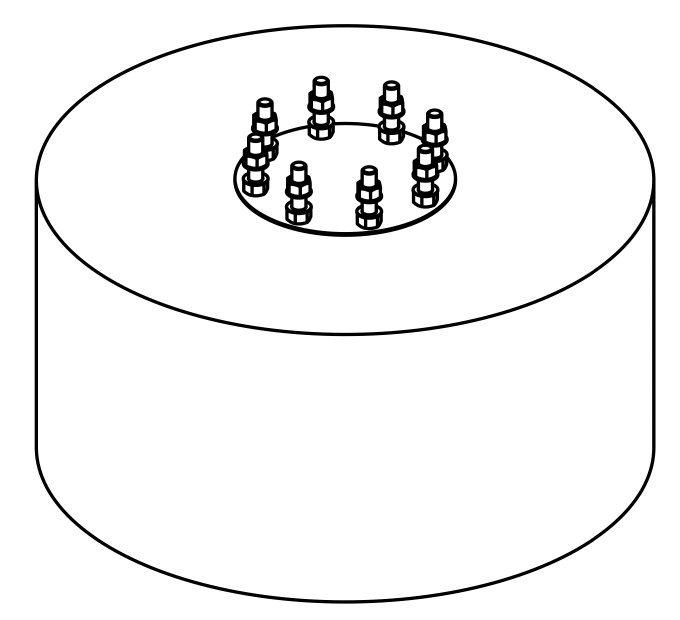

If you want to use concrete, you will need to dig a large hole and fill it with a cubic metre of concrete, ready for the circular aluminium concrete base plate to float on the top - see illustration. See our assembly guide for full instructions on all the different mounting options. These two systems both use concrete mounts. Concrete mounting is a far less eco friendly option than ground anchors.

Bedrock:

Bedrock will require drilling holes, flushing with compressed air to create a clean bonding surface, and then chemical glue to hold the bolts.